Grooved Wood Veneer

Specification:

Width:600mm,800mm,1220mm

Length:2440mm,2800mm,2900mm,3000mm

Thickness:5mm,7mm,8mm

Density:0.75,0.8

We support size and color customization

Description

1. Product ingredients

WPC wood veneer (wood plastic composite material) is a kind of natural plant fiber (such as wood chips, bamboo chips, rice husks, straw, etc.) and polymer plastics (such as polyethylene PE, PVC, polypropylene PP, etc.) as the main raw materials, by adding chemical additives (such as antioxidants, anti-ultraviolet agents, flame retardants, etc.) mixed, by high temperature extrusion molding of new environmental protection materials.

Core component ratio: plant fiber accounts for about 50%-70%, plastic accounts for about 30%-50%, supplemented by a small amount of functional additives.

Environmental protection features: Raw materials are mostly used waste wood or agricultural by-products, the production process is free of harmful substances such as formaldehyde and benzene, and can be 100% recycled.

2. Product specifications and dimensions

WPC wood finishes can be customized to a variety of specifications, common types include:

Thickness: 0.5cm,0.7cm,0.75mm0.8mm.

Width: 600mm,1220mm

Length: 2440mm-3000mm.

Sizes and colors can be customized.

3. Product features

WPC wood finishes combine the benefits of both wood and plastic with the following core features:

Environmental protection and health

Zero formaldehyde, no heavy metal pollution, the testing standard is better than the EU E0 level 4 times, to achieve Japan F four-star environmental protection certification.

Strong durability

Waterproof and moisture-proof (water absorption rate ≤1%), anti-moth, anti-ultraviolet, outdoor service life of up to 20-50 years.

High wear resistance (surface wear resistance ≤ 0.08g /100 RPM), impact resistance (can withstand 27 tons of weight).

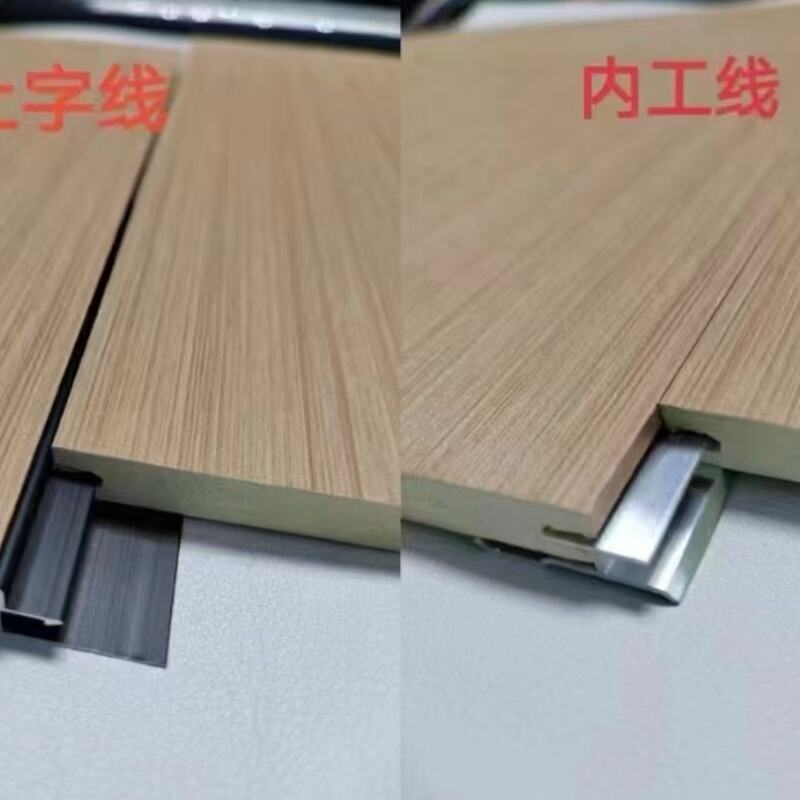

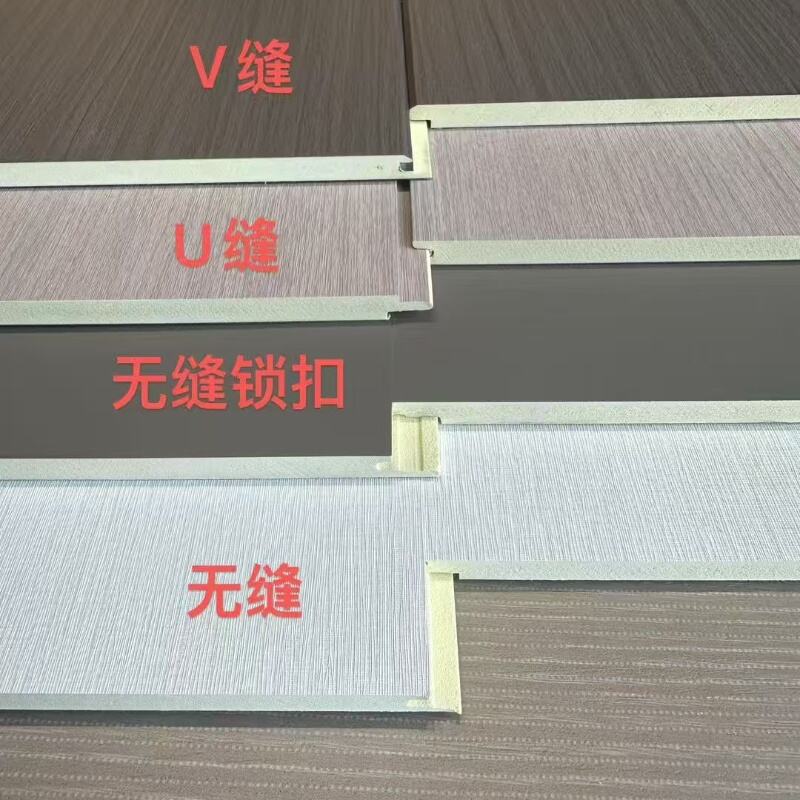

Convenient processing

Support saw, planing, nail, drilling and other secondary processing, nail holding force of 1000N (plate surface), flexible installation.

Using dry assembly installation, no bricklayer, shorten the construction period by 4-5 times.

Stable performance

Good dimensional stability (expansion rate ≤2.5%), poor temperature resistance (-40℃ to 70℃).

Flame retardant level up to B1, thermal insulation (thermal conductivity 0.08W /m·K, better than traditional walls).

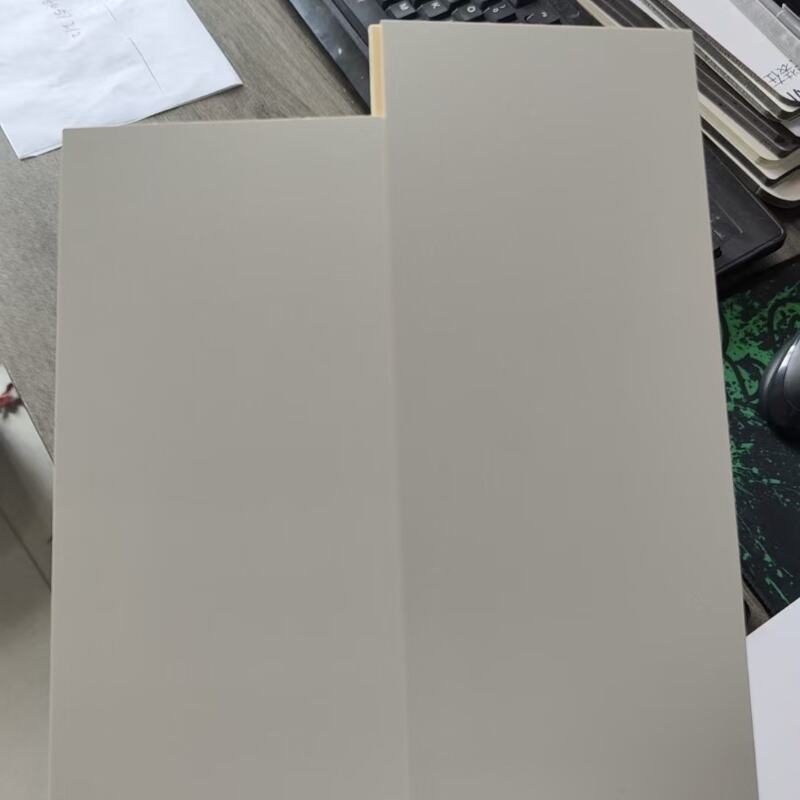

Highly decorative

The surface can be customized wood grain, stone grain and other textures, diverse colors, gloss can be adjusted to meet the needs of modern aesthetics.

4. Application Scenarios

WPC wood finishes are widely used in the following scenarios:

Indoor scene

Decoration: wall panel, ceiling, skirting line (no static electricity, dust proof and easy to clean).

Commercial space: shopping malls, hospitals, office buildings (antibacterial, fireproof, sound-absorbing).

Industry and logistics

Pallet, packing box (lightweight, high load), traffic barrier (acid and alkali corrosion resistance).